T30 axial flow fans are widely used in factories, warehouses, offices, and residences for ventilation or to enhance heating and heat dissipation.

Application of fan: This series of products is suitable for the explosive gas mixture (zone 1 and zone 2) of IIB grade T4 and below grades, and is used for ventilation of workshops and warehouses or to strengthen heating and heat dissipation.

The working conditions of this series of products are: AC 50HZ, voltage 220V/380V, no places with heavy corrosion and significant dust.

1. Overview of fan products

1. The purpose of the fan

T30 axial flow fans are widely used in factories, warehouses, offices, and residences for ventilation or to enhance heating and heat dissipation. It can be used as a free fan, or it can be installed in series in a long exhaust duct to increase the wind pressure in the duct. The gas passing through the fan should be non-corrosive, non-spontaneous, and non-obvious dust, and its temperature should not exceed 45°.

BT30 explosion-proof axial flow fan, the impeller part is made of aluminum material (except the shaft disc), the power is changed to an explosion-proof motor, and an explosion-proof switch or switch is used to keep away from the explosive point. The other parts are of the same material as the axial flow fan. It is mainly used in the chemical, pharmaceutical, textile and other industries and for the discharge of flammable, explosive and volatile gases. The installation process and other processes are the same as those of the axial flow fan.

2. Type of fan

There are 46 varieties of this fan, of which there are nine machine numbers for blades, 6 blades, 8 blades, and 8 blades. According to the diameter of the impeller, the order from small to large is: No. 3, No. 3.5, No. 4, No. 5. No. 6, No. 7, No. 8, No. 9, No. 10; among them, there are ten machine numbers for the 4-blade, according to the size of the impeller diameter, the order from top to large is: No. 2.5, No. 3, No. 3.5, №4, №5, №6, №7, №8, №9, №10.

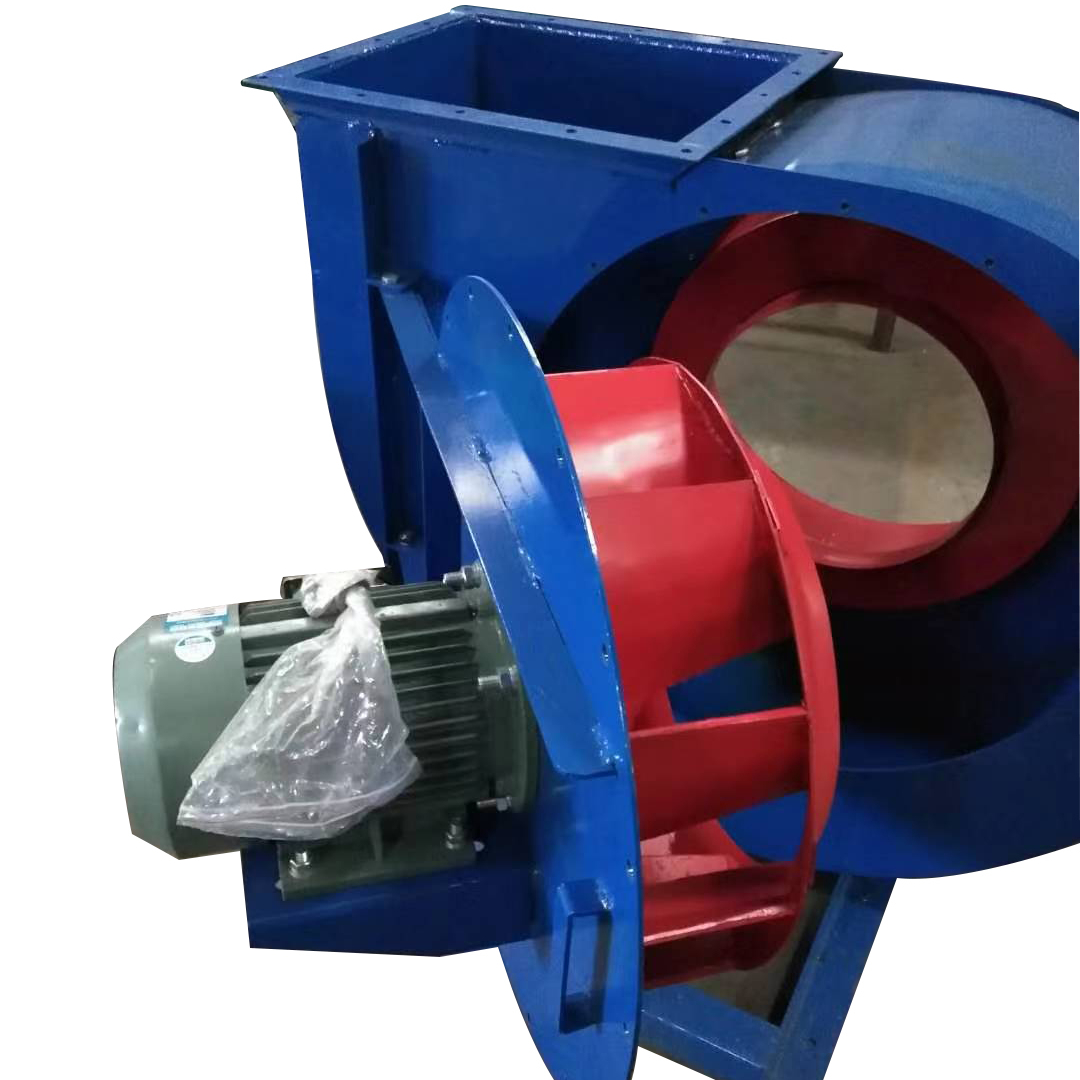

3. The structure of the fan

The fan consists of three parts: impeller, casing and biaser:

(1) Impeller - consists of blades, hubs, etc. The blades are stamped and formed with thin steel plates and welded to the outer circle of the hub according to the required installation angle. The impeller-to-shell ratio (ratio of shaft disk diameter to impeller diameter) is 0.3.

(2) Blades—both are punched into similar shapes, and their installation angles: 3 pieces are divided into five types: 10°, 15°, 20°, 25°, 30°; №4, №6, №8 are divided into five types 15°, 20°, 25°, 30°, 35° five kinds. The impeller is directly installed on the motor shaft, among which 3 uses two motor speeds, No. 9 and No. 10 use one motor speed, the air volume ranges from 550 to 49,500 cubic meters per hour, and the wind pressure ranges from 25 to 505Pa.

(3) Cabinet - consists of air duct, chassis, etc. The chassis is divided into two types made of thin plates and profiles.

(4) The transmission part consists of a main shaft, a bearing box, a coupling or one of the discs. The main shaft is made of high-quality steel, and the bearings are rolling bearings. There is enough volume in the bearing housing to place the cooling oil, and there is an oil level indicator to ensure normal operation.

(5) Air collector - arc streamlined, stamped from a thin plate to reduce the energy loss at the inlet.

2. Fan performance parameters and selection table

|

Type |

Machine NO. |

Air volume |

T.P |

Rotating speed |

Motor capacity |

Noise decibel |

Weight |

|

|

1 |

2 |

|||||||

|

Wall-mounted |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

29 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

32 |

|

|

5 |

5700 |

147 |

1400 |

0.3 |

63 |

69 |

35 |

|

|

6 |

11000 |

245 |

1400 |

0.55 |

72 |

76 |

42 |

|

|

Post type |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

34 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

38 |

|

|

5 |

5700 |

147 |

1400 |

0.3 |

63 |

69 |

43 |

|

|

6 |

11000 |

245 |

1400 |

0.55 |

72 |

76 |

55 |

|

|

Pipeline |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

31 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

35 |

|

|

5 |

5700 |

147 |

1400 |

0.55 |

72 |

76 |

70 |

|

|

6 |

11000 |

245 |

1400 |

0.55 |

72 |

76 |

70 |

|

|

Stationary |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

32 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

36 |

|

|

5 |

5700 |

147 |

1400 |

0.3 |

63 |

69 |

40 |

|

|

6 |

11000 |

245 |

1400 |

0.55 |

72 |

76 |

55 |

|

|

Dustproof |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

33 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

38 |

|

|

5 |

5700 |

147 |

1400 |

0.3 |

63 |

69 |

43 |

|

|

6 |

11000 |

245 |

1400 |

055 |

72 |

76 |

52 |

|

|

Roof mounted |

3 |

2280 |

101 |

1400 |

0.18 |

61 |

64 |

64 |

|

4 |

3000 |

118 |

1400 |

0.3 |

61 |

64 |

70 |

|

|

5 |

5700 |

147 |

1400 |

0.3 |

63 |

69 |

85 |

|

|

6 |

11000 |

245 |

1400 |

0.55 |

72 |

76 |

98 |

|